The IAG 550 Short Block is designed for modified EJ25 Subarus that need a stronger short block to support increased cylinder pressures created by additional boost pressure. The IAG 550 short block features IAG Spec H-Beam forged connecting rods. The upgraded connecting rods and race bearings are able to support additional engine load produced by larger turbochargers or increased boost which the OEM STI rods found in the Stock short blocks cannot support reliably.

IAG 550 2.5L Short Block 2006-2014 WRX / 2004-2021 STI

IAG 550 EJ25 2.5L SUBARU SHORT BLOCK

DESIGNED FOR STRENGTH

BUILT WITH 100% NEW COMPONENTS

Each IAG 550 Short Block starts with brand new EJ25 Subaru 2.5L, 99.5mm stock bore engine case halves as standard. The case haves are carefullly measured and assembled using a new 2017+ Subaru 2.5L nitride treated STI crankshaft, which is matched to ACL or King race main bearings. The IAG 550 Short Block features IAG Spec H-Beam Connecting Rods with ARP2000 rod bolts, along with ACL or King race rod bearings. The case halves are sealed with new OEM main case bolts and sealant. Finally, IAG Spec JE 99.5mm Forged Pistons are carefully selected, measured, and installed to finish off the short block.

FORGED PISTONS, DESIGNED FOR BOOST

Each IAG 550 Short Block features IAG Spec JE 99.5mm Forged Pistons. These 2618 T6 Alloy high-strength pistons have been specifically designed to support increased cylinder pressures which come with more boost. This is accomplished by using an asymmetrical skirt design instead of the traditional full-round skirt, also this reduces weight significantly. Featuring smooth flowing radii on the domes and dishes, the design promotes excellent flame travel. The pistons are secured to the rods with .905 x 2.250" x .180" wall carbon steel wrist pins with Tru Arc locks.

What's Inside:

IAG 550 Short Block Includes:

- Case Halves -Brand new Subaru OEM case halves 99.5mm stock bore

- Pistons -IAG-Spec JE 99.5mm Forged Pistons, Ring Set, .180" Chromoly Pins, Clips, (Perfect Skirt Coating and Offset Wrist Pin)

- Connecting Rods -IAG-Spec H-Beam Rods with ARP2000 rod bolts

- Rod / Main Bearings -ACL or King Race Bearings

- Crankshaft -Standard New Subaru Nitride Treated 2017+ STI Crankshaft

- Case / Main Bolts -Standard FHI Subaru case bolt

- Compression Ratio:8.5:1 on D Cylinder Heads (EJ255), 8.2:1 on B, V, and W EJ257 Heads with standard thickness gasket.

Power Rating:

The IAG 550 Short Block has a power output rating of 550 BHP

Hardware / Seal Option:

Not planning on reusing your original short block service plugs and covers? IAG offers a simple comprehensive cover and seal kit that includes (1) Rear main seal, (3) OEM wrist pin plugs, (3) OEM wrist pin plug washers, (1) OEM separator cover, (6) OEM separator cover bolts, (1) OEM wrist pin service cover, (1) OEM wrist pin service cover O-ring and (2) OEM wrist pin service cover screws. *If you are reusing your original wrist pin service plugs and covers always replace the (3) OEM wrist pin plug washers and (1) wrist pin service cover O-ring before installing a short block to avoid potential leaks. *Never reuse a rear main seal on a new short block.

Oil Pickup / Oil Baffle / Windage Tray Options:

The IAG Performance Subaru WRX / STI oil pickup was designed by Tigwerks to replace the OEM EJ25 oil pickup, which is prone to failure. It's a well-known fact that the OEM oil pickups often crack and fail which, in most cases, destroys your engine from lack of oil pressure. To avoid the cracking failures seen in the OEM oil pickup tubes, the Tigwerks oil pickup is manufactured from heavy-gauge steel tubing that is 3x thicker than OEM. Additionally, it features a flange machined from 3/8"Â 1018 CR steel to mate with the block, sealed with a Viton O-ring. The integrated heavy-duty mounting bracket uses two mounting points rather than the OEM single mounting point. Furthermore, the oil pickup features a formed bottom with an OEM style mesh screen for proper filtration. The TIG-welded oil pickup's increased material thickness, matched with the two-point heavy-duty mounting bracket, helps ensure that it does not fatigue and fail over time like an OEM unit.

The IAG Oil Control Baffle and Windage Tray System is designed to limit potential blow-by and prevent oil starvation in your Subaru's WRX / STI EJ engine during high rpm and high g-force driving. Through the use of Viton one-way flapper valves on our baffle and louvers in our windage tray, oil is prevented from reentering the upper crankcase area and is directed down into the oil pan to ensure plentiful supply to the oil pickup. IAG's integrated two-piece Oil Control Baffle and Windage Tray System is designed to work with our own oil pickup, as well as other oil pickups*. The baffle fits neatly in the engine crankcase area, allowing normal installation of the OEM oil pan and popular aftermarket pans*.

Oil Pickup & Baffle Install Notes

- EJ20 Subaru WRX engines require EJ25 oil pans for fitment

- IAG oil pickup spacer (Part# IAG-ENG-2081SP) is required when using IAG oil pickup with Killer B Oil Pan.

- *Does not work with Moroso oil pans or pickups

Oil Pump Option:

The 11mm Subaru Oil pump is one of the most popular off the shelf pumps to use on EJ25 engines. Originally equipped on the 2008-21 STI Dual AVCS engines, it provides an adequate amount of pressure and flow that fits the needs of many OE and built engines. But, as with almost anything, there is room for improvement.

Increasing oil flow volume and pressure in an EJ25 ensures that the bearings have sufficient oil film under all power levels and driving conditions. Additional oil flow to the engine provides a greater oil reserve to operate the AVCS solenoids and cam gears - giving you more consistent performance results.

The IAG Stage 2 CNC Ported 11mm oil pump was developed over years of servicing street and racing engines. In that time IAG has tested and utilized the majority of the popular Subaru oil pumps available on the market (JDM, Cosworth, ACL etc.) for customer, personal and racing vehicles.

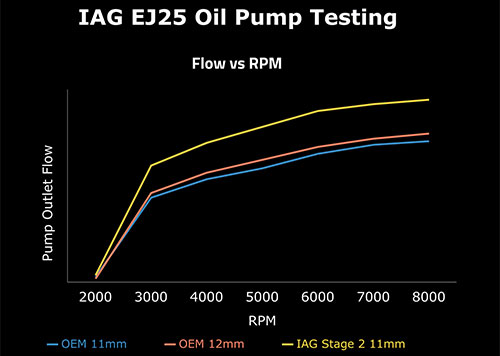

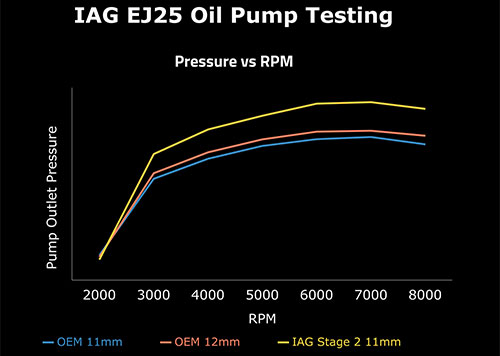

Over the last few years if you wanted an upgraded oil pump over the stock 11mm you would either buy a hand ported model from a trusted source, or often an OEM JDM (Japanese Market) 12mm pump. We believe that we have developed a better alternative. The IAG Stage 2 CNC Ported 11mm oil pumps have shown through lab testing on a Spintron Machine that it will outperform a JDM 12mm.

- Stage 2 flows 11.1% more oil than the OEM 11mm Oil Pump

- Stage 2 flows 9% more oil than the OEM 12mm Oil Pump

- Stage 2 oil pressure is 12.4% higher than the OEM 11mm Oil Pump

- Stage 2 oil pressure is 9.8% higher than the OEM 12mm Oil Pump

The Stage 2 Oil pump is a cost effective solution that outperforms the market standards. This pump has been extensively tested on street cars, track cars, and on our in-house Spintron to ensure consistent and repeatable performance.

Each IAG Stage 2 oil pump starts life as an OEM spec 11mm oil pump, straight from Subaru. IAG completely disassembles the new oil pump including pulling the rotors, backing plate & pressure relief valve. Next, the main body is fixtured in our in-house 5-Axis Centroid CNC machine where the inlet and outlet passageways are CNC ported. This allows for a larger, more consistent pathway for the oil into and out of the gerotor internals and helps to prevent cavitation. The Oil Pump Outlet where it meets the engine block is also CNC “Port Matched”, for a perfect transition into the engine block. The Inlet and Outlet sides of the gerotor are also opened up on the CNC mill to reduce inlet side cavitation, and to reduce outlet side pressure drops.

The pressure relief valve piston is REM Polished, which provides a non-directional, low Ra, polished finish. This reduces friction, heat and possibility of the relief valve piston galling and sticking, a common failure point on the OEM pumps.

The piston is reinstalled and confirmed to operate correctly. The rotors are measured and checked to be within the manufacturer's specification - aka Blueprinted, and installed next. The pump is then put together with a light coating of assembly lube to reduce friction and scuffing and aid in priming on first start up.

Finally, the backing plate is installed. Loctite is added to the hardware, and each piece receives a painted mark after it is correctly torqued. The pump ships ready to install, with all hardware and seals required for installation.